Achieving Superior Completed With In-Mold Decorations in Production

Achieving Superior Completed With In-Mold Decorations in Production

Blog Article

Grasping In-Mold Decorations: Methods, Patterns, and Best Practices for Optimum Outcomes

In the world of production, the art of in-mold designs stands as a pivotal aspect of product design and production. As industries continuously look for innovative means to improve visual charm and performance, grasping the details of in-mold decors has emerged as a vital capability. From choosing the right products to including innovative design fads, the journey in the direction of accomplishing ideal cause this domain is complex. By diving into the methods, patterns, and finest techniques that underpin effective in-mold decoration processes, businesses can unlock a realm of possibilities that not just boost the visual allure of their products however likewise improve production efficiency and bolster customer engagement.

Material Option

Product choice is a critical element of grasping in-mold decors, as it directly influences the top quality and toughness of the last product. When selecting materials for in-mold decors, it is important to consider factors such as compatibility with the molding procedure, the desired visual result, and the ecological problems the product will certainly deal with.

Additionally, products with high heat resistance are preferred for in-mold decors, especially for products that will be revealed to elevated temperature levels during their lifecycle. By thoroughly selecting the ideal material for in-mold decorations, producers can improve the overall quality and toughness of their products, satisfying the assumptions of both end-users and clients - In-Mold Decorations.

Design Technology

A vital aspect in advancing the field of in-mold decors is the constant expedition and execution of design development strategies. Layout technology plays an important role in enhancing the aesthetic allure, functionality, and total high quality of items produced utilizing in-mold design processes. By incorporating cutting-edge layout aspects, producers can distinguish their products out there, attract customers, and remain in advance of competitors.

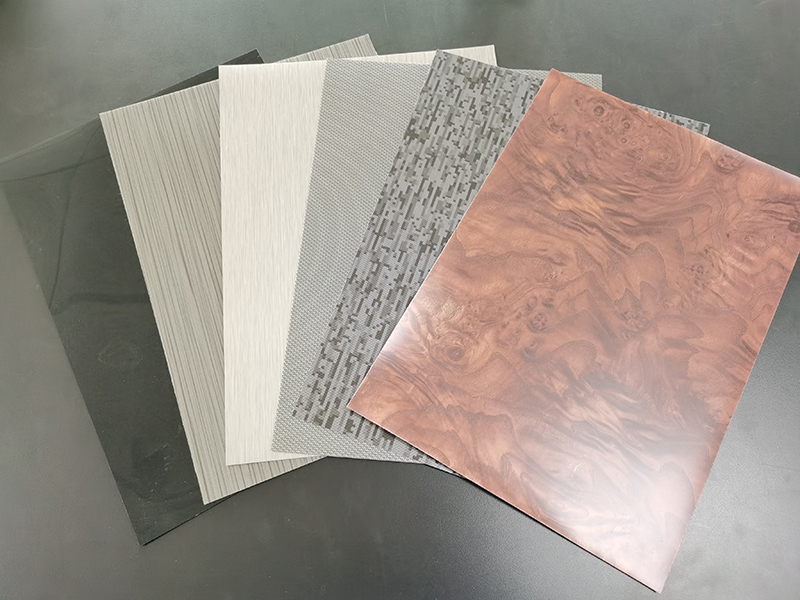

Among the essential aspects of design technology in in-mold designs is the assimilation of intricate patterns, appearances, and graphics that were previously challenging to accomplish with standard decor techniques. Advanced modern technologies such as 3D printing and electronic layout tools make it possible for designers to create facility and comprehensive designs that can be perfectly transferred onto molded parts. Furthermore, making use of vivid colors, metallic coatings, and special effects like gloss or matte textures can better elevate the aesthetic allure of in-mold decorated products.

Moreover, design innovation prolongs beyond aesthetics to include practical enhancements such as ergonomic shapes, integrated functions, and personalized aspects that provide to specific customer requirements. By accepting layout technology, makers can open new opportunities for personalization, creativity, and product differentiation in the affordable landscape of in-mold designs.

Manufacturing Efficiency

Effective manufacturing procedures are vital for converting the innovative layouts established in the field of in-mold decors right into premium completed items that meet market demands and consumer expectations. In the world of in-mold designs, manufacturing efficiency includes numerous essential facets that add to the general success of the production process. One vital aspect is the optimization of mold layout and tooling to ensure smooth and precise decoration address transfer onto the end product. By fine-tuning mold configurations and buying top notch tooling products, makers can enhance effectiveness and uniformity in manufacturing.

Additionally, carrying out automation and robotics in the assembly line can substantially boost efficiency by streamlining repetitive jobs and decreasing the margin of error. Automation not only increases the production process yet likewise boosts accuracy and repeatability, causing a much more high-quality and uniform end product. Embracing lean production concepts, such as just-in-time stock management and waste decrease techniques, can even more enhance manufacturing efficiency by decreasing downtime and enhancing source application. On the whole, a holistic method to manufacturing efficiency is critical in making the most of the potential of in-mold decoration strategies and accomplishing optimum results in the competitive market landscape.

Quality Assurance Measures

What are the crucial techniques for making sure rigorous top quality control procedures in the realm of in-mold designs? Quality control measures are vital in in-mold decor processes to guarantee the manufacturing of flawless and high-grade finished products.

Making use of innovative technologies such as automated examination systems can also boost the high quality control procedure by giving precise and trusted information for analysis. These systems can identify imperfections that may be missed out on by manual examinations, consequently enhancing overall product high quality and consistency.

Regular training and advancement programs for employees associated with the in-mold decoration procedure can also add to maintaining top quality criteria. By educating personnel on ideal practices, high quality assumptions, and the importance of focus to detail, firms can promote a culture of high quality awareness throughout the organization.

Consumer Appeal

To enhance the marketability of in-mold decoration products, understanding and providing to consumer choices play an essential role in determining their appeal and success. Supplying modification choices such as individualized layouts, shade variations, and textural aspects can substantially improve the allure of in-mold design products.

Verdict

In-mold decors supply a flexible and efficient method to enhance item appearances. Mastering in-mold decors calls for an all natural strategy that thinks about all facets of the manufacturing informative post process to guarantee success.

In the world of manufacturing, the art of in-mold designs stands as a crucial facet of item design and production. Style development plays an essential duty in enhancing the aesthetic charm, capability, and total high quality of products manufactured using in-mold design processes.One of the vital aspects of layout advancement in in-mold decorations is the integration of intricate patterns, textures, and graphics that were previously challenging to achieve with conventional design techniques.Efficient manufacturing processes are vital for converting the cutting-edge layouts established in the field of in-mold decors into top notch completed items that satisfy market needs and customer assumptions. Providing customization alternatives such as individualized designs, shade variations, and textural components can dramatically boost the appeal of in-mold decoration products.

Report this page